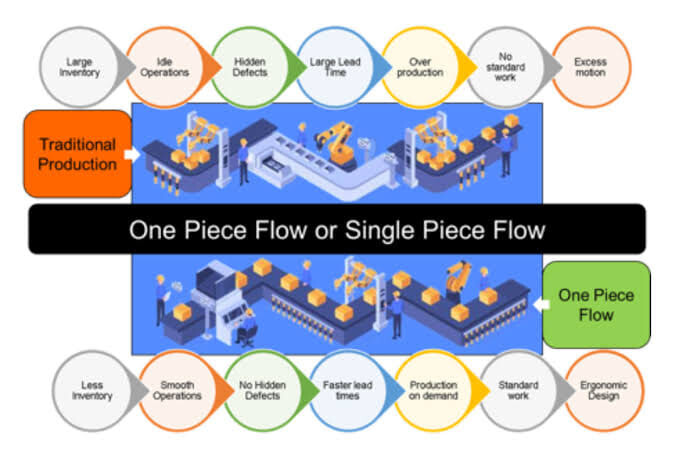

Single-piece flow is a production system where each unit of product is processed sequentially without waiting or batching. This means that products move through the production process in a continuous flow, with minimal or no waiting time between steps.

Benefits of Single-Piece Flow

- Reduced lead time: By eliminating wait times and bottlenecks, single-piece flow can significantly reduce lead times.

- Improved quality: Single-piece flow can help to improve quality by making it easier to identify and correct defects.

- Increased productivity: By reducing waste and improving efficiency, single-piece flow can increase productivity.

- Enhanced flexibility: Single-piece flow can make it easier for businesses to respond to changes in customer demand.

- Improved employee morale: Single-piece flow can create a more satisfying and rewarding work environment for employees.

Implementing Single-Piece Flow

Implementing single-piece flow can be challenging, but it is possible with careful planning and execution. Here are some tips for implementing single-piece flow:

- Identify bottlenecks: Identify the areas of your production process that are causing bottlenecks.

- Reduce setup time: Minimize the time it takes to set up equipment for production.

- Balance the workload: Ensure that the workload is evenly distributed among workstations.

- Use a pull system: Implement a pull system to ensure that products are produced only when they are needed.

- Continuously improve: Single-piece flow is an ongoing process, and businesses should continue to seek ways to improve their implementation.

Challenges of Single-Piece Flow

Some of the challenges of implementing single-piece flow include:

- High initial costs: Implementing single-piece flow can require significant investments in new equipment and training.

- Disruptions: Single-piece flow can be disrupted by unexpected events, such as equipment failures or supply chain disruptions.

- Resistance to change: Employees may resist changes to their work processes.

Conclusion

Single-piece flow is a powerful tool that can help businesses improve efficiency, quality, and productivity. However, it is important to carefully consider the challenges and benefits before implementing single-piece flow in your organization.