Poka Yoke

🌟 Introduction to Poka Yoke

In today's competitive manufacturing landscape, achieving zero defects isn't just an aspiration—it's a necessity for survival. Enter Poka Yoke, a revolutionary quality control methodology that has transformed how organizations approach error prevention and quality assurance.

Developed in the 1960s by Japanese industrial engineer Shigeo Shingo, Poka Yoke represents a fundamental shift from reactive quality control to proactive error prevention. Rather than catching defects after they occur, this methodology focuses on designing systems that make errors impossible or immediately detectable.

As a cornerstone of Lean Manufacturing and Six Sigma methodologies, Poka Yoke has proven its effectiveness across industries—from automotive and electronics to healthcare and software development. Its principles have saved companies millions of dollars while improving customer satisfaction and operational efficiency.

📚 History and Origins

The Visionary: Shigeo Shingo

The story of Poka Yoke begins in post-World War II Japan, when the nation was struggling to rebuild its manufacturing reputation. "Made in Japan" was synonymous with cheap, low-quality products, and Japanese manufacturers desperately needed to compete with established Western brands.

The Birth of an Idea

Shigeo Shingo, working at Toyota, observed a factory worker repeatedly installing parts incorrectly. Instead of blaming the worker, Shingo redesigned the part to make incorrect installation impossible.

Toyota Adoption

Toyota began implementing Poka Yoke principles across their production lines, leading to significant improvements in quality and efficiency.

Global Recognition

As Japanese automotive quality gained worldwide recognition, Western companies began studying and adopting Poka Yoke principles.

Universal Application

Poka Yoke principles expanded beyond manufacturing into healthcare, software development, services, and everyday product design.

From Baka-Yoke to Poka-Yoke

This name change reflects a fundamental aspect of Poka Yoke philosophy: respect for people. The methodology doesn't blame individuals for mistakes but recognizes that human error is natural and focuses on improving systems to prevent these errors.

🎯 What Does Poka Yoke Mean?

Poka Yoke is derived from two Japanese words:

- Poka (ポカ) = Inadvertent mistake or error

- Yoke (ヨケ) = Prevention or avoidance

Core Definition

Poka Yoke is a quality control technique that makes it impossible or difficult to make mistakes, or makes mistakes immediately obvious once they occur. It's about designing processes, products, and systems to guide users toward the correct action and away from errors.

The Philosophy Behind Poka Yoke

Shingo differentiated between two critical concepts in manufacturing:

Human Mistakes

Inevitable errors that occur due to:

- Forgetfulness

- Misunderstanding

- Poor judgment

- Fatigue

- Lack of attention

Defects

The result when mistakes are:

- Not prevented

- Not detected immediately

- Allowed to reach customers

- Built into the final product

🎪 Objectives and Goals

The primary objective of Poka Yoke is to achieve zero defects through systematic mistake prevention and detection. This ambitious goal is accomplished through several key approaches:

Primary Objectives

🛡️ Prevention Focus

- Eliminate defect generation at the source

- Make mistakes impossible to occur

- Design fool-proof processes and systems

- Reduce dependency on human vigilance

- Create inherently safe operations

🔍 Detection & Correction

- Immediate identification of mistakes

- Real-time correction capabilities

- Prevent defects from reaching customers

- Enable continuous process improvement

- Provide feedback for system enhancement

🎯 Strategic Objectives

- Quality Excellence: Achieve consistent, predictable quality outcomes

- Cost Reduction: Eliminate waste from defects, rework, and inspection

- Customer Satisfaction: Deliver defect-free products and services

- Employee Empowerment: Create systems that support worker success

- Competitive Advantage: Build reputation for reliability and excellence

⚡ Types of Poka Yoke

Poka Yoke systems are categorized into two main types based on their approach to handling errors:

🚫 Prevention Type

Philosophy: Make errors impossible to occur

Prevention-type Poka Yoke systems are designed so that defects or mistakes simply cannot happen. The process or product is engineered to eliminate the possibility of error.

Prevention Methods:

- Elimination: Remove error opportunities entirely

- Prevention: Block incorrect actions

- Replacement: Substitute error-prone elements

- Facilitation: Make correct actions easier

🔍 Detection Type

Philosophy: Catch errors immediately when they occur

Detection-type systems allow mistakes to occur but provide immediate detection, alerting, and correction mechanisms before defects reach customers.

Detection Methods:

- Detection: Identify when errors occur

- Alerting: Signal the occurrence of mistakes

- Correcting: Fix errors immediately

- Mitigating: Reduce error impact

🏆 Prevention vs. Detection: Which is Better?

In manufacturing industries, prevention-type Poka Yoke is generally preferred over detection-type because:

- It eliminates waste associated with error occurrence

- It requires no human intervention or response

- It prevents downstream complications

- It provides absolute reliability

However, detection-type systems are valuable when prevention isn't technically or economically feasible.

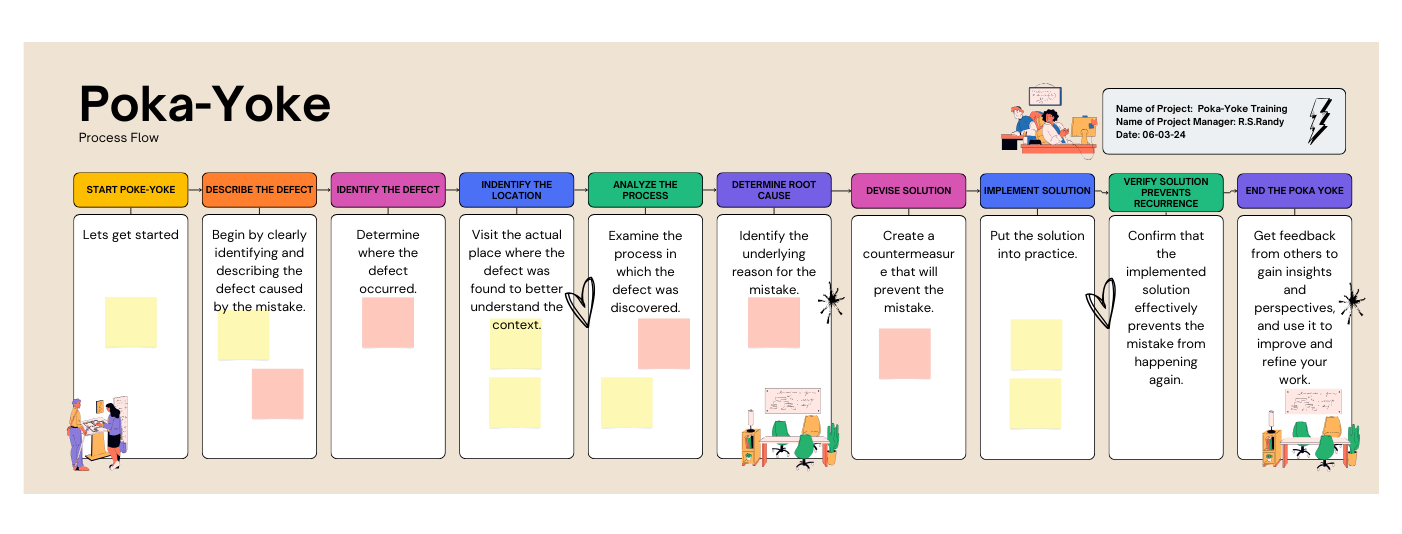

🛠️ Implementation Steps

Successful Poka Yoke implementation follows a systematic, seven-step approach that ensures comprehensive error prevention and detection:

Step 1: Process Review

Objective: Identify error opportunities

- Map complete manufacturing process flow

- Identify where human mistakes are likely

- Use tools like PFC and PFMEA

- Analyze historical defect data

- Interview operators and supervisors

Step 2: Source Identification

Objective: Pinpoint root causes

- Identify source of each defect/error

- Use root cause analysis techniques

- Categorize by 6Ms factors

- Prioritize high-impact errors

- Document error patterns

Step 3: Process Re-design

Objective: Eliminate error chances

- Re-design process to prevent errors

- Apply prevention-type solutions first

- Consider ergonomic factors

- Simplify complex operations

- Test redesigned processes

Step 4: Detection System

Objective: Catch unavoidable errors

- Implement detection systems

- Choose appropriate sensors/devices

- Set up immediate alerts

- Enable quick correction

- Prevent downstream impact

Step 5: Method Selection

Objective: Choose optimal solutions

- Evaluate available methods

- Consider cost vs. benefit

- Select appropriate devices

- Match solution to error type

- Ensure maintainability

Step 6: Implementation

Objective: Deploy solutions

- Install mistake-proofing systems

- Train operators on new procedures

- Conduct pilot testing

- Validate effectiveness

- Document new processes

Step 7: Monitoring

Objective: Ensure continued effectiveness

- Monitor system performance

- Track error reduction metrics

- Maintain equipment regularly

- Update procedures as needed

- Continuous improvement

- Employee Involvement: Engage workers in identifying and solving problems

- Management Support: Ensure leadership commitment and resources

- Systematic Approach: Follow all steps methodically

- Continuous Improvement: Regularly review and enhance systems

🎛️ Regulatory Approaches

Poka Yoke devices can be implemented using two primary regulatory functions that determine how the system responds to detected errors:

🛑 Control Approach

Action: Stops the process immediately

- Senses error/problem occurrence

- Automatically stops machine/process

- Forces corrective action before continuation

- Prevents defective products from advancing

- Ensures 100% error correction

⚠️ Warning Approach

Action: Alerts without stopping

- Signals error occurrence through:

- Visual indicators (lights, displays)

- Audio alerts (buzzers, alarms)

- Haptic feedback (vibration)

- Continues operation while alerting

- Relies on human response

- Logs errors for analysis

🎯 Choosing the Right Approach

Use Control Approach When:

- Defects create safety hazards

- Errors are expensive to correct later

- Quality requirements are absolute

- Regulatory compliance is mandatory

Use Warning Approach When:

- Stopping production is very costly

- Errors can be corrected downstream

- Human judgment is needed

- Process flexibility is important

⚙️ Poka Yoke Methods and Devices

Poka Yoke systems employ three fundamental methods for preventing and detecting errors. Each method can be implemented using either Control or Warning approaches:

📏 Contact Method

Principle: Physical inspection of product attributes

What it Checks:

- Size and dimensions

- Shape and geometry

- Color and appearance

- Texture and surface finish

- Weight and mass

- Temperature

Common Devices:

- Limit switches: Detect position/presence

- Pressure sensors: Monitor force/pressure

- Proximity sensors: Non-contact detection

- Vision systems: Optical inspection

- Go/No-go gauges: Dimensional verification

🔄 Motion/Sequence Method

Principle: Verification of operational sequence

What it Monitors:

- Correct operation sequence

- Proper timing of steps

- Required motion completion

- Process flow adherence

- Safety procedure compliance

Implementation Examples:

- Sequence sensors: Track operation order

- Timer circuits: Monitor duration

- Motion detectors: Verify movements

- Interlock systems: Enforce sequences

- RFID tracking: Process verification

🔢 Fixed-Value/Counting Method

Principle: Verification of quantities and counts

What it Counts:

- Number of parts/components

- Quantity of operations

- Number of movements

- Event occurrences

- Cycle completions

Device Examples:

- Digital counters: Electronic counting

- Parts feeders: Pre-counted supplies

- Weight scales: Quantity by weight

- Optical counters: Light-beam counting

- Torque monitors: Fastener counting

🔧 Device Selection Criteria

Technical Factors:

- Accuracy requirements

- Response time needs

- Environmental conditions

- Integration complexity

Economic Factors:

- Initial investment cost

- Maintenance requirements

- Training needs

- Return on investment

Operational Factors:

- Reliability requirements

- Ease of use

- Maintenance complexity

- Scalability needs

🎯 Sources of Errors

Understanding the root causes of errors is essential for effective Poka Yoke implementation. Manufacturing and service errors typically stem from six primary sources, known as the 6Ms factors:

👨🔧 Man (Human)

Common Issues:

- Fatigue and attention lapses

- Lack of training or skills

- Forgetfulness or memory errors

- Misunderstanding instructions

- Poor communication

- Rushing to meet deadlines

🏭 Machine

Common Issues:

- Equipment breakdowns

- Calibration drift

- Wear and tear

- Software glitches

- Sensor failures

- Power fluctuations

📋 Method

Common Issues:

- Unclear procedures

- Complex processes

- Missing work instructions

- Outdated methods

- Inconsistent practices

- Poor standardization

🧱 Material

Common Issues:

- Quality variations

- Wrong specifications

- Contamination

- Mixed lots/batches

- Storage problems

- Supplier defects

📏 Measurement

Common Issues:

- Calibration errors

- Instrument precision limits

- Reading mistakes

- Recording errors

- Unit conversions

- Gauge repeatability

🌍 Mother Nature (Environment)

Common Issues:

- Temperature variations

- Humidity changes

- Vibration effects

- Dust and contamination

- Lighting conditions

- Noise interference

🔍 Error Analysis Framework

When implementing Poka Yoke, consider that errors often result from combinations of these factors. A systematic analysis should:

- Identify primary and secondary causes from the 6Ms

- Understand interaction effects between different factors

- Prioritize high-impact combinations for immediate attention

- Design multi-layered protection for complex error sources

🏭 Real-World Examples

Poka Yoke principles are implemented across diverse industries and applications. Here are practical examples that demonstrate the power of mistake-proofing:

Manufacturing Examples

🔒 Machine Safety Interlocks

Problem: Operators might start machines with safety doors open

Solution: Machine won't operate until all safety doors are closed and locked

Type: Prevention + Control Approach

Benefit: Eliminates injury risk, ensures safety compliance

🔧 Fixture Design

Problem: Parts installed in wrong orientation

Solution: Fixtures designed to hold parts in correct orientation only

Type: Prevention + Contact Method

Benefit: Eliminates assembly errors, improves quality

⚠️ Missing Parts Detection

Problem: Drilling operations sometimes missed

Solution: Locator pins at next station detect missing holes

Type: Detection + Warning Approach

Benefit: Catches errors before final assembly

✋ Two-Hand Operation

Problem: Risk of operator injury on press machines

Solution: Machine requires both hands on separate buttons to operate

Type: Prevention + Control Approach

Benefit: Keeps hands away from dangerous areas

🔢 Screw Counting System

Problem: Wrong number of screws in assemblies

Solution: Pre-counted screw dispensers and torque monitors

Type: Prevention + Fixed-Value Method

Benefit: Ensures correct fastener count

🎨 Color-Coded Systems

Problem: Wrong materials or tools selected

Solution: Color coding for different grades/types

Type: Prevention + Contact Method

Benefit: Visual identification prevents mix-ups

Everyday Poka Yoke Examples

🏠 Home & Personal

- USB Connectors: Designed to fit only one way

- Car Keys: Engine won't start without proper key

- Microwave Ovens: Won't operate with door open

- Washing Machines: Won't start with lid open

- Gas Pumps: Different nozzle sizes for different fuels

- Child-proof Bottles: Require special action to open

🏢 Office & Technology

- Email Systems: "Are you sure?" confirmations

- ATM Cards: Can only be inserted one way

- Power Plugs: Three-prong design prevents reversal

- Software: Input validation and error messages

- Elevators: Won't move with doors open

- Printers: Paper guides prevent misalignment

Service Industry Applications

🏥 Healthcare

- Patient wristbands with barcodes

- Medication packaging with verification

- Surgical checklists and time-outs

- Equipment alarms and monitors

- Color-coded medical gas connectors

🍔 Food Service

- Temperature alarms for refrigeration

- Timer systems for cooking

- Portion control devices

- Hand-washing reminder systems

- Order verification displays

🏦 Banking & Finance

- Two-factor authentication

- Transaction limit controls

- Address verification systems

- Duplicate payment prevention

- Account number validation

🎉 Benefits and Advantages

Implementing Poka Yoke systems delivers substantial benefits across multiple dimensions of business performance. Organizations that successfully deploy mistake-proofing typically see improvements in quality, costs, productivity, and customer satisfaction.

Primary Benefits

🛡️ Error Prevention

Eliminates mistakes before they occur, creating inherently reliable processes

🔍 Immediate Detection

Catches errors instantly when prevention isn't possible, enabling quick correction

📈 Quality Improvement

Delivers consistent, predictable quality in products and processes

💰 Cost Reduction

Eliminates waste from defects, rework, scrap, and warranty claims

😊 Customer Satisfaction

Prevents defects from reaching customers, improving satisfaction and loyalty

⚡ Higher Productivity

Reduces time spent on inspection, rework, and problem-solving

👥 Worker Benefits